Over the last decade,

lean six sigma has become a popular strategical imperative in many businesses to ensure continuous improvement. It’s use in the manufacturing industry has become so popular that it has changed the face of manufacturing forever and is implemented in every aspect of the industry right from people to machinery, and administration to logistics.

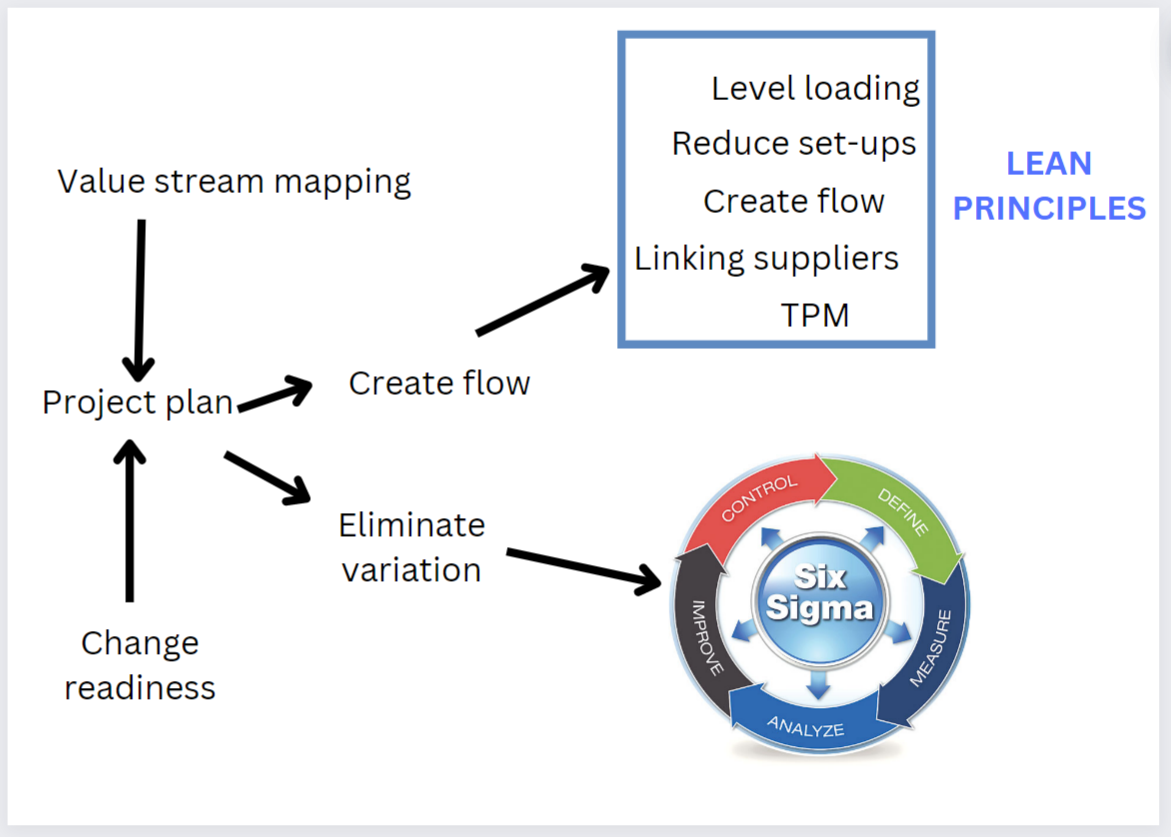

The integration of the 2 separate concepts of lean and six sigma seem to be a proven solution that can overcome the shortcomings of both methods and complete each other to effectively reduce complaints, errors and improve delivery timelines.

Here’s a roadmap of how an integrated approach, of lean and six sigma, can lead to process improvement in a manufacturing unit.

Applying the basics of lean six sigma to manufacturing

Most manufacturers are focussed on increasing customer value and satisfaction, but in the process have lost the primary vision of the company’s success – profitable growth and this takes much more than quick fixes or downsizing.

Applying the principles of lean six sigma to manufacturing can help increase profitability while maintaining or increasing customer satisfaction.

A study conducted by Ben Reuben in an automative component manufacturing firm which produces high precision transmissions located in Tamil Nadu, India. The study used the lean six sigma concepts to practically validate operational and environmental benefits.

After application of the lean six sigma principles the following benefits were observed:

- Internal defects reduced from 16000 ppm to 600 ppm

- Environmental impact lowered from 42 Pt to 33 Pt

The lean six sigma tools used were 5S, kaizen, quality function deployment, cause and effect diagram, value-stream mapping, Pareto chart, environmental VSP, cost benefit analysis, life cycle interpretation, 7s practices, performance evaluation tools, standard operating procedures (with environmental metrics), etc.

Lean six sigma is highly beneficial in the manufacturing sector. However, it is important that practitioners are aware of the various tools, techniques, concepts and methodologies before initiating it.

Reference: Bhaskar HL. IntechOpen 2020. Lean Six Sigma in Manufacturing: A Comprehensive Review

DOI: 10.5772/intechopen.89859

The integration of the 2 separate concepts of lean and six sigma seem to be a proven solution that can overcome the shortcomings of both methods and complete each other to effectively reduce complaints, errors and improve delivery timelines.

Here’s a roadmap of how an integrated approach, of lean and six sigma, can lead to process improvement in a manufacturing unit.